Rosafety Solutions SRL,

oferă soluții integrate de Securitate și Sănătate în Muncă și Managementul Situațiilor de Urgență pentru activitățile desfășurate de operatorii economici indiferent de sectorul de activitate.

Consultanță pentru Securitatea și Sănătatea în Muncă

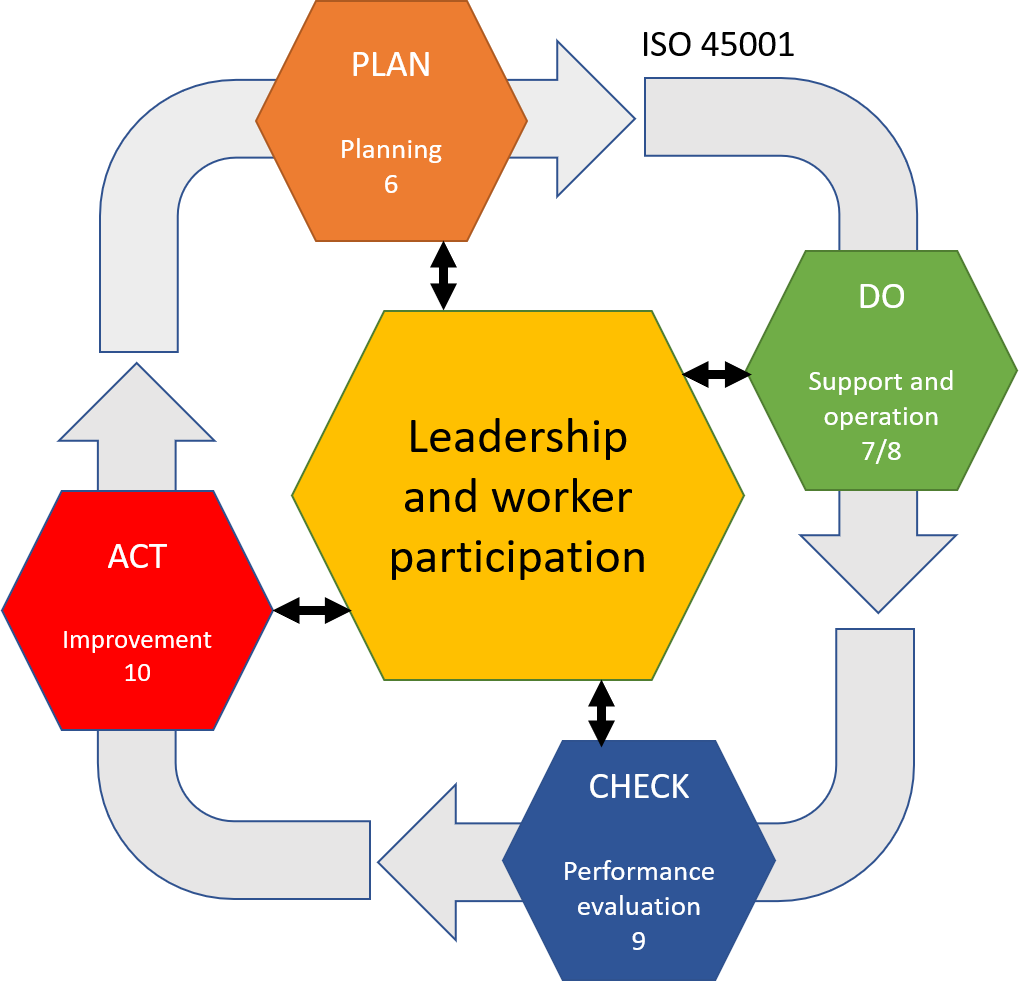

Serviciile noastre acoperă toate cerințele pentru securitate și sănătate în muncă menționate in legislația națională și europeană. Asigurăm implementarea unui sistem de Management al Sistemului de Securitate și Sanatate în Muncă (nu și certificarea acestuia)

- Evaluarea riscurilor de accidentare și îmbolnăvire profesională

- Serviciu extern de prevenire și protecție

- Auditul Securităţii și Sănătăţii în Muncă

- Acte de autoritate pentru Securitate și Sănătate în Muncă

Pentru detalii accesați secțiunea Securitate și Sănătate în Muncă

Consultanță pentru Situații de Urgență

Serviciile noastre în domeniul Situațiilor de Urgență acoperă cerințele minime privind întocmirea actelor de autoritate, a planurilor de evacuare și intervenție cât si activitățile privind instruirea personalului. De asemenea, asigurăm consultanță pentru intocmirea necesarului si inventarului echipamentelor de intervenție în caz de incendiu sau pentru situații de urgență

- Prevenirea și Stingerea Incendiilor

- Situații de Urgență

- Audit de conformitate pentru Situaţii de Urgenţă

- Acte de autoritate pentru Situaţii de Urgenţă

Pentru detalii accesați secțiunea Situații de Urgență

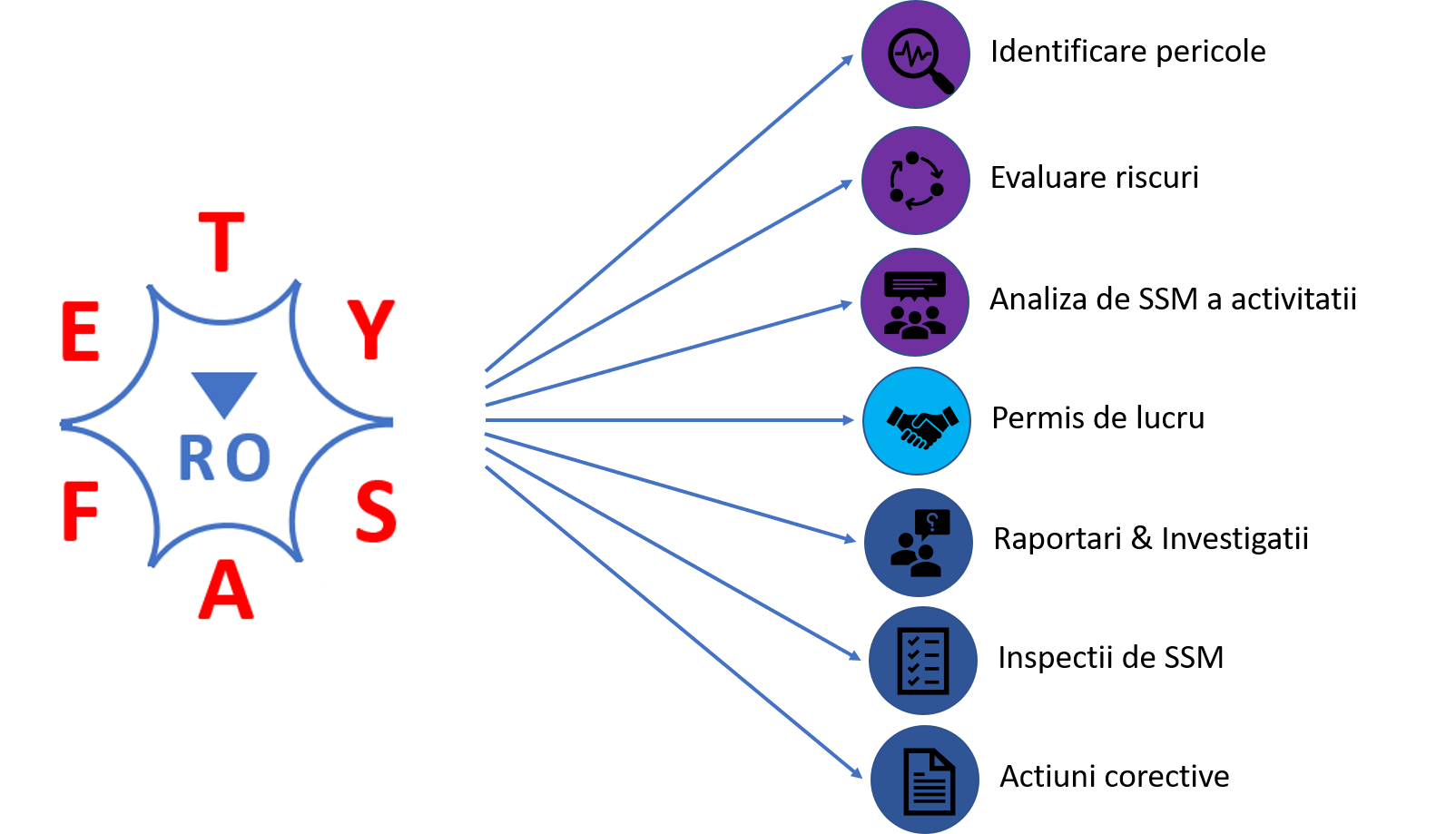

Permisul de lucru

Permite utilizatorilor autorizati sa pregateasca si sa emita un Permis de lucru, online, utilizand un computer, o tableta sau un telefon conectat la internet

Identificarea pericolelor

Identificarea pericolelor este primul pas in implementarea unor conditii sigure de munca

Evaluarea riscurilor de accidentare

Pentru fiecare pericol trebuie evaluate efectele si frecventa actiunii acestuia asupra personalului, echipamentelor, mediului si a reputatiei companiei

Analiza de SSM a activitatii (JSA)

Dezvoltati proceduri de lucru si efectuati o analiza de SSM pentru activitatea efectuata

Raportari conditii periculoase

Raportarea actiunilor gresite, a conditiilor periculoase sau incidentelor periculoase care nu au produs daune sau vatamari corporale joaca un rol important in prevenirea incidentelor grave.

Inspectii de SSM

Implicarea managementului in identificarea locurilor de munca cu pericole sau a actiunilor gresite induc imbunatatirea comunicarii pe verticala si imbunatatirea conditiilor de SSM

Raportarea incidentelor/accidentelor

In cazul nefericit in care un incident sau un accident de munca au loc, detaliile evenimentelor trebuie inregistrate pentru investigatiile ulterioare.

Investigarea incidentelor

Aplicatia permite investigarea incidentelor sau accidentelor prin identificarea cauzelor de profunzime si generarea de actiuni corective

Permisul de lucru

Initiaza si emite un Permis de lucru online sau genereaza un fisier pdf care poate fi printat. Tipurile de Permise de lucru pot fi definite si adaugate dupa cerintele fiecarei companii. Permisul de lucru permite identificarea pericolelor asociate activitatii efectuate si a masurilor de protectie, masurarea si inregistrarea valorilor de oxigen, LEL si/sau gaze toxice inainte, in timpul si la finalizarea activitatii si, daca este cazul, implementarea unui Certificat de izolare. Personalul cu atributii de SSM poate efectua analize a Permiselor de lucru si emite rapoarte pentru monitorizarea implementarii unor conditii sigure de munca. Rapoarte grafice si statistici sunt disponibile in sectiunea StatisticiIdentificarea pericolelor

Identificarea pericolelor este procesul de identificare și înregistrare a tuturor pericolelor posibile care sunt sau pot fi prezente la locul de muncă. Identificarea pericolelor face parte din procesul de evaluare a riscurilor în care pericolele sunt identificate și evaluate astfel încât să fie stabilite măsuri adecvate pentru a le elimina sau a controla efectul acestora.Evaluarea riscurilor si masuri de protectie

Efectuați o Evaluare a riscurilor pentru cuantificarea efectelor pericolelor identificate asupra oamenilor, echipamentelor, mediului sau reputației companiei dvs. Utilizați Scala de risc încorporată pentru a lua măsuri pentru riscuri care nu pot fi tolerate prin identificarea controalelor (tehnice, administrative, PPE sau supraveghere). Aveți o imagine de ansamblu asupra riscurilor companiei dvs. prin Registrul riscurilor. Când este necesar, elaborați o Analiza de SSM a activitatii pentru lucrarile efectuate de personal propriu sau de contractori, revizuită de Departamentul de SSM și aprobată de conducerea dvs.Analiza de SSM a activitatii (JSA)

Analiza de SSM a activitatii (JSA) este un instrument de management al siguranței în care sunt identificate pericolele și masurile de control specifice activitatilor efectuate. Procesul JSA este documentat, iar documentul JSA este utilizat la locul de muncă pentru a-i ghida pe lucrători în ceea ce privește securitatea si sanatatea locului de muncă.Raportarea conditiilor pericoloase, a incidentelor si accidentelor

Un sistem robust de raportare a Actiunilor gresite, Conditiilor periculoase, Incidentelor periculoase, Accidentelor, si efectuarea unei Investigatii de tip DE CE? sau Analiza a cauzelor de profunzime pot preveni accidentele majore. Aceste investigatii vor genera Actiuni corective care vor avea un responsabil pentru implementare si pot fi monitorizate.Permiteti personalului sa faca sugestii de imbunatatire a conditiilor de securitate si sanatate in munca prin Sugestii pentru SSM , analizate de personalul cu atributii de SSM si, daca este cazul, implementate.

Inspectii de SSM

Înregistrați constatările Inspectiilor de SSM pentru o urmărire mai ușoară a implementării și monitorizarea conditiilor care se repeta. Inspecțiile de SSM sunt o modalitate excelentă de a face referire la angajamentul față de practicile de lucru în condiții de siguranță, de a asigura conștientizarea siguranței și de a minimiza pericolele la locul de muncă. De asemenea, oferă o metodă sistematică de implicare a sefilor de compartimente, angajaților, personalului cu atributii in SSM și / sau comitetelor de SSM în procesul de eliminare a pericolelor la locul de muncă.Raportarea Accidentelor

Raportarea accidentelor este esențială, deoarece sensibilizează organizația cu privire la lucrurile care pot merge prost, astfel încât acțiunile corective și preventive să poată fi puse în aplicare cu promptitudine. De asemenea, creează lecții învățate în cadrul organizației, contribuind la o cultură sporită a siguranței Reporting Incidents is essential since it raises the organization’s awareness about the things that can go wrong so that corrective and preventative actions can be implemented promptly. It also creates lessons learned within the organization contributing to an enhanced safety cultureInvestigarea incidentelor si a accidentelor

Incidentele trebuie investigate dacă este vorba despre Actiuni gresite, Conditii periculoase, Incidente fara pagube materiale sau vatamari corporale sau Accidente. Investigațiile relevă eficacitatea controlului pericolelor într-o organizație și identifică cauzele de profunzime înainte ca un alt incident similar să devină un incident grav. Obiectivul investigației este de a identifica cauza principală. Fie un simplu DE CE? sau o Analiza a cauzelor de profunzime, rezultatul investigatiilor sunt Actiuni corective, necesare pentru prevenirea recurenței